PVD Coating & Cutting Tool Solutions At The 2023 SHOT Show

Dayton Coating Technologies and Certified Tool & Grinding will be attending the ultimate supplier showcase trade show again this year, with quality PVD Coating and Cutting Tool solutions for the Firearm Industry.

The SHOT Show is a highly dedicated trade show. Suppliers can exhibit a variety of materials, tools, machinery, as well as other products and services for the shooting, hunting, outdoor and law enforcement industries.

At the 2023 SHOT Show, we will be showcasing our precise manufacturing of new one-step operations that we have been intricately developing. Our team of experts have engineered highly effective solutions, in order to combine and merge numerous processes into just one, single tool solution.

PVD Coating Solutions For Firearms & Defense Weapons

The precision engineering and power behind firearms and defense weapons is what, ultimately, makes the need for quality treatment and tooling solutions essential. Our industry-leading, quality services and exceptional, highly skilled team can provide you with real PVD Coating Solutions.

Dayton Coating Technologies can guarantee a high performance PVD Coating for firearms and defense weapons – a coating that is durable and looks fantastic.

PVD is known as Physical Vapor Deposition. Your firearms and manufacturing tools are going to achieve maximum efficiency, when they have a PVD Coating. With our quality PVD Coating process, your machined parts and cutting tools will accurately obtain hardness and abrasion resistance. The significantly thin application of our PVD coatings will make sure that there is no perceivable thickness acquired on your firearm’s parts, properly staying within tolerance.

The hardness of a PVD coating will not affect the characteristics of the steel underneath. A PVD Coating’s hardness is going to, essentially, provide excellent abrasion resistance and an even lower coefficient of friction, which is going to result in less sliding resistance reversal and faster feed rates, without wear.

Benefits Of A PVD Coated Firearm | Defense Weapon:

- Hard, scratch & wear resistant

- Lubricous, corrosion & chemical resistant

- Beautiful color

- No appreciable build-up interfering with firearm operation

- Can be thoroughly applied over a high polish finish

It is highly recommended that you keep your coated parts oiled, in order to prevent corrosion. Be careful of your coating provider’s PVD process. Use a PVD coating company that specifically knows how to not overheat your steel.

PVD Coating Attributes:

- Thin coatings that are 2 to 5 microns – minimal impact on size tolerance

- Low friction coefficients – minimizes friction losses

- High adhesion to a wide range of steels

- Ability of deposit alloyed & multilayered coatings

- Ability to mask regions, where no coating is desired

- Zero environmental impact – no effluents or toxic chemical

Typical PVD Coating Colors

Dayton Coating Technologies offers a diverse range of PVD Coating colors, depending upon the chemical composition of that particular coating.

- Gold (TiN)

- Rose Gold (TiCN)

- Dark Grey (AlTiN)

- Blue Grey (AlCrN)

- Pale Gold (Zirconium Nitride)

In each coating, the specific amount of carbon might vary a little. This may result in a PVD coated part varying, just slightly, in color. In addition to that, it is important to understand that different surfaces on one single part, coated with the exact same coating, will appear to be slightly different in color, as well. These slight variations, in color, will in no way impact the performance of a firearm or defense weapon.

FFL 045 PVD Coating Processes

The classic Gold (TiN) or Rose Gold (TiCN) PVD Coating will come with underlying improvements that provide, both, a beautiful and functional finish. Each process is made to effectively handle the rigors of classic competition that you are accustomed to.

The Titanium Carbo Nitride is unique, in terms of firearm finishes. This PVD coating not only offers a custom look to your firearm, but it also adds durability and reduces the friction on the coated part. A PVD coating, like the Titanium Nitride, adds only 3 micrometers of thickness. Therefore, it will enhance the function and the look of your firearm, without causing any interference to the part’s functionality and performance.

FFL 308 PVD Coating Process

The gray dense nano-structured PVD Coating process was developed to support power related wear issues. This coating can efficiently handle both wear and impact.

A gray dense nano-structured coating comes with a matte or reflective finish.

Expect this product to be darker in color, especially when the coating is applied to a matte or blasted oiled finish.

FFL 223 PVD Coating Process

This particular coating is a treated, superlattice, high performance and dense PVD Coating that will provide a sustained performance, in the most demanding environment.

This PVD Coating is hard and tough, with incredible erosion and thermal resistance.

Treatments For Firearm Components

A pre – treatment can, also, be applied to your firearm components. Pre – treatments are implemented to provide different surface finishes. Such as:

- Matte

- Semi-Matte

- Polished

Oftentimes, a firearm represents an investment. You want to be sure that each firearm component receives the best treatment that is possible, in order to ensure many trouble-free hours of shooting.

Our vertical integrations will make sure that your parts effectively receive a full suite of treatment solutions. All of our coating processes are precisely designed, in order to successfully protect your firearm from wear.

Cutting Tool Solutions For Firearms & Defense Weapons

Certified Tool & Grinding is widely known for being a trusted leader in efficiently manufacturing precision gun tools for Firearms and Defense Weapons. We successfully help major manufacturing companies extend the life of their cutting tools.

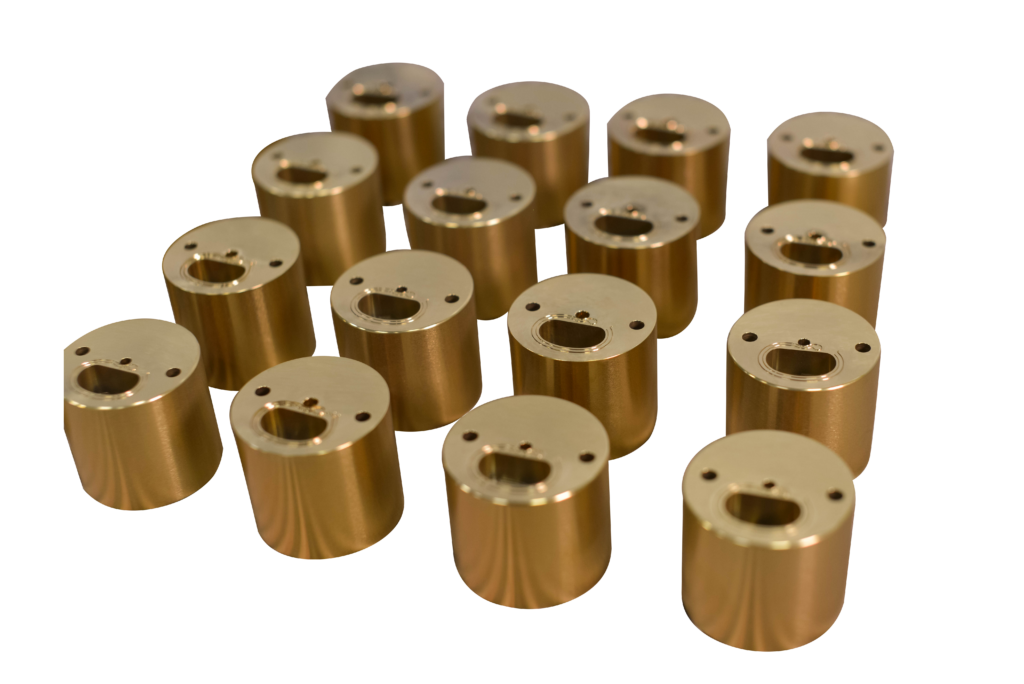

A precision firearm or defense weapon is going to begin with Precision Tooling. Our team can manufacture a wide variety of solid carbide cutting tools. For instance:

- End Mills

- Reamers

- Form Cutters for Rifle Barrel Machining

- Component Milling

- Drilling Operations

Extend The Life Of Your Firearm Manufacturing Process

Our experienced engineering team can help you with your most complex challenges. We can provide you with exceptional accuracy, in order to meet the exact tolerances of the firearm industry. Equipped with state-of-the-art machinery, we properly meet the growing demands and accurately attain the creative visions of our customers regularly.

That same precision, expertise and commitment to quality will go into helping you extend the life of your firearm manufacturing process, with our vertically integrated in-house PVD coating array.

FFL Magnum Cutting Tool Process

The Certified Tool & Grinding FFL Magnum collection will provide Cutting Tools that are specifically designed for the machining of specialized firearm alloys. These cutting tools are designed to, both, customer supplied part geometry and our engineering expertise modified standards, because there is no “one-size-fits-all” solution, especially when it comes to tooling for Firearm Manufacturing.

As a manufacturer, it is necessary that a Cutting Tool accurately fits your precise needs. That is why Certified Tool & Grinding is proud to offer a fully custom tool design, for all of your firearm and gun tool applications.

Firearms are complex and precise machines that require highly detailed standards on every piece, in order to ensure that the firearm operates with reliability and safety, as intended. Our engineering team is eager to design a custom tool that is specific to your unique manufacturing requirements. Custom cutting tools designed by our engineers can guarantee a precise and repeatable cut, every single time.

Solutions For The Firearm Industry

Come and join Dayton Coating Technologies and Certified Tool & Grinding at the trade show – Booth 52423. Take part in understanding the latest, most advanced products and developments in the industry. Find the tools that you need, in order to improve productivity and performance.

The 2023 SHOT Show Supplier Showcase will take place on January 16 and 17 in Las Vegas, Nevada. The shooting, hunting and outdoor trade show will accommodate over 500 suppliers, who will be showcasing a wide variety of solutions for your manufacturing company’s needs.

The highly anticipated 2023 SHOT Show is right around the corner and we can not wait to see you there!

Whether you are in need of a quote or application support, our expert engineering team is eager to assist you with your cutting application, in order to successfully develop your company’s unique solution. Our highly skilled coating team is, additionally, dedicated to providing you with real PVD Coating solutions. We strive to exceed our customers’ expectations in quality, accuracy, repeatability and delivery.

Do not hesitate to contact our team if you have any questions or a unique application that you need support with. You can, also, follow our Dayton Coating | Certified Tool & Grinding LinkedIn page, to stay up to date with industry trends and news.