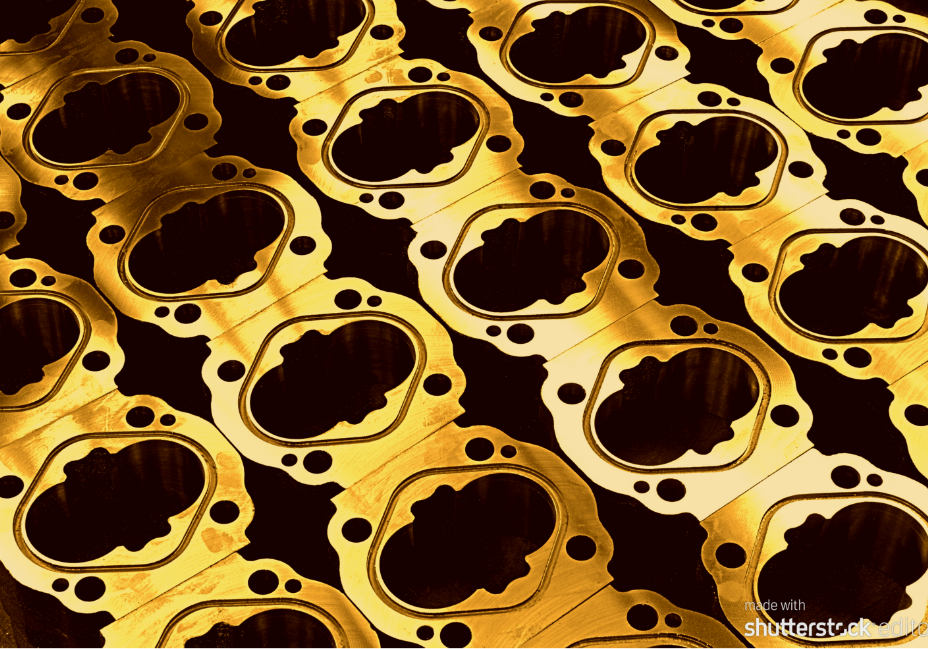

Metal Packaging

Smooth coatings and repeatable performance are only a few benefits offered by our premier Bev Coatings. With our combination of vertically integrated services, surface preparations and a highly disciplined team, we help you make an exceptional finished product, on time, every time. Highlights:

- Delicate Score Line Care

- Smooth Surface Finishes

- 100% Inspection

- Reduced Edge Build-Up

- Cutting Tools Engineered Specifically for Food & Beverage Tooling Characteristics

Let's Get Started

Metal Packaging PVD BENEFITS

- Improved instrument performance

- Barrier layer for various solutions

- Decreased friction with improved wear resistance

BEV CLASSIC

Strong historical record of results with 100% incoming / outgoing inspection

Our Bev Classic process provides a highly repeatable line of standard composite structure PVD coatings with 100% pre and post-production inspection and a recorded history of dynamic results. This highly repeatable, uniform line of coating includes TiN, AlTiN, TiCN, and others that are tailored for food & beverage industry tooling.

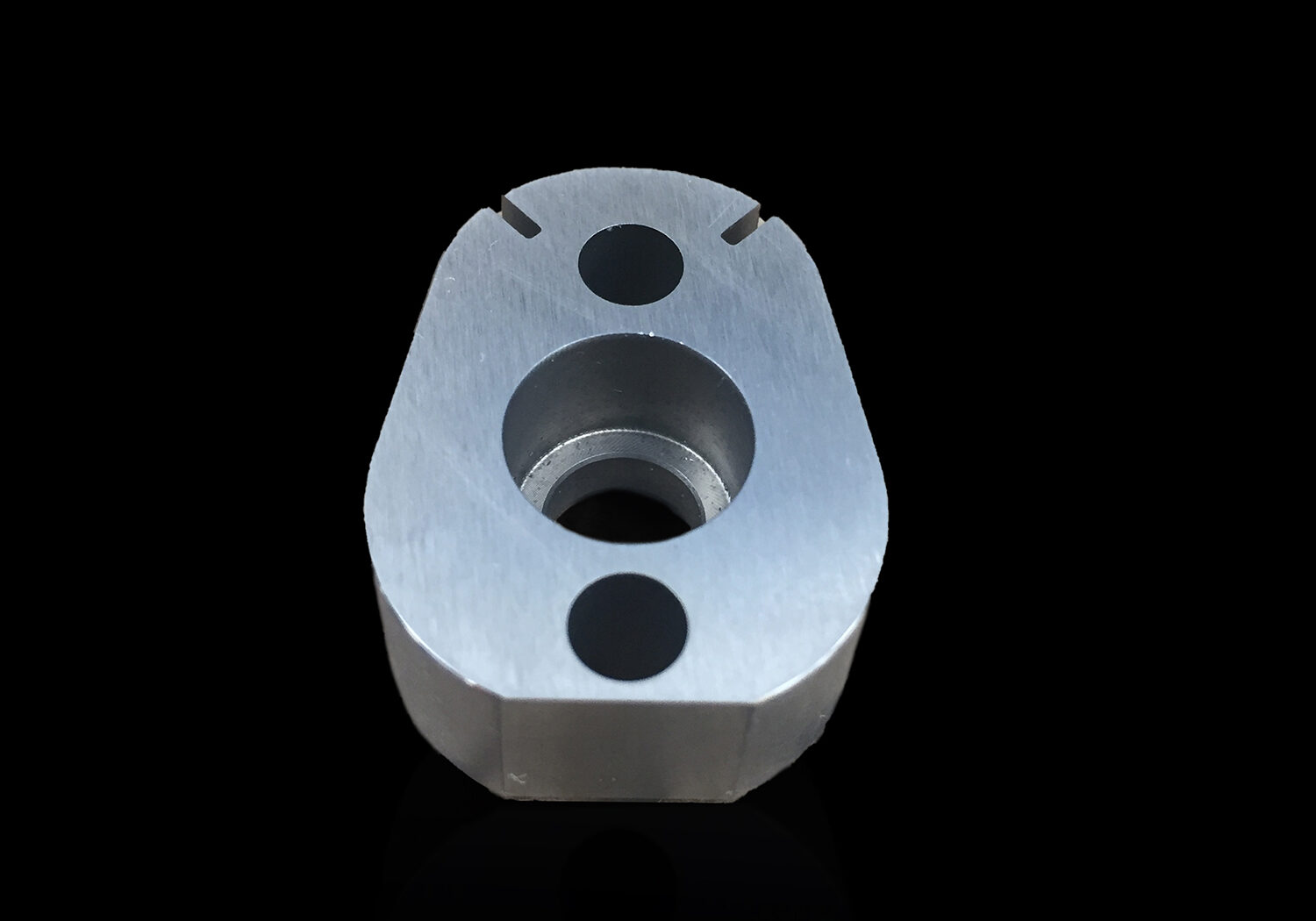

SMART BEV

A new solution to some old challenges. A coating that can last for various super high precision applications

This leading-edge tool room solution produces a highly repeatable coating for polished parts. Smart Bev is an all-inclusive process that includes deburring and inspection combined with super lattice, erosion-resistant, PVD products such as AlCrN-HC.

PUNCH FORCE

Best blend of our newest technology including pulsed arc deposition with diffusion.

Our aptly named Punch Force process is your total tool solution for punch galling, soldering, edge wear, and erosion. Punch Force tools have been engineered and blended with the newest technology, including our proprietary PVD treatment with diffusion, specifically for your manufacturing operation. This repeatable high-performance tooling is designed to last longer and save you time.

LET’S GET STARTED.

Ready to find the perfect tool, machining or PVD coating solution? Get started today.