MEDICAL COMPONENT COATING

From biocompatible coatings to high-performance tools used in medical part production, we have the perfect manufacturing solution for your operation. We are experienced with selective medical quality requirements and provide rigid technical solutions. All instruments and coatings are 100% inspected pre and post production and processed with specialized quality procedures by our on-staff tribological engineering support team.

Highlights:

- Tight, Precision Masking

- Superior Coating Adhesion

- Experts at Working with 300 Series Substrate

- Medical Part and Coating Training Available

- Medical Part Manufacturing Specifications Available for Purchase

- Erosion Resistant Parts with Correlative Thickness Control

MEDICAL, ROBOTIC, & PROSTHETIC PVD BENEFITS

- Improved Instrument Performance

- Barrier Layer for Various Solutions

- Decreased Friction with Improved Wear Resistance

- Excellent erosion resistance

- Increased lubricity

- Autoclave Compatible

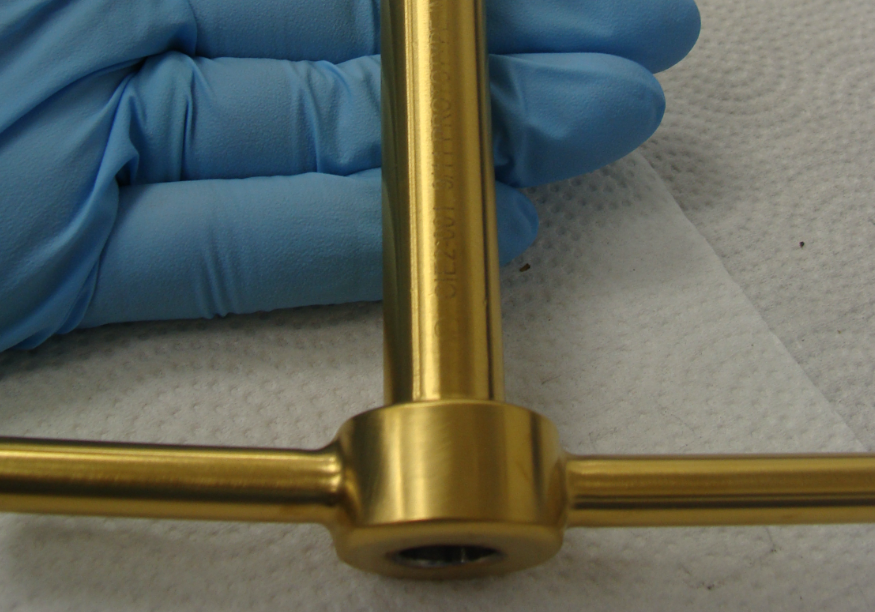

MEDSPEC COATING

This high quality, biomedically tested Instrument coating line is validated for 24 hour exposure. Precision, tight masking ensures coating is applied only to critical areas of your instrument leaving a clean masking line and reliable surface.

LET’S GET STARTED.

Ready to find the perfect tool, machining or PVD coating solution? Get started today.