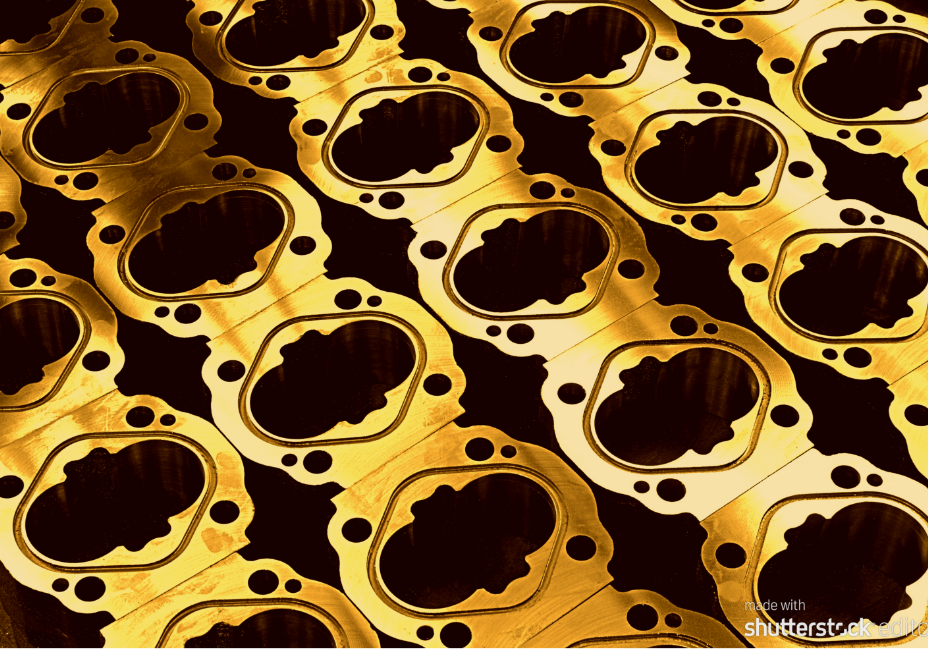

Metal Packaging

Smooth coatings and repeatable performance are only a few benefits offered by our premier Bev Coatings. With our combination of vertically integrated services, surface preparations and a highly disciplined team, we help you make an exceptional finished product, on time, every time. Highlights:

- Delicate Score Line Care

- Smooth Surface Finishes

- 100% Inspection

- Reduced Edge Build-Up

- Cutting Tools Engineered Specifically for Food & Beverage Tooling Characteristics

Let's Get Started

Metal Packaging PVD BENEFITS

- Improved instrument performance

- Barrier layer for various solutions

- Decreased friction with improved wear resistance

BEV CLASSIC

Strong historical record of results with 100% incoming / outgoing inspection

Our Bev Classic process provides a highly repeatable line of standard composite structure PVD coatings with 100% pre and post-production inspection and a recorded history of dynamic results. This highly repeatable, uniform line of coating includes TiN, AlTiN, TiCN, and others that are tailored for food & beverage industry tooling.

SMART BEV

A new solution to some old challenges. A coating that can last for various super high precision applications

This leading-edge tool room solution produces a highly repeatable coating for polished parts. Smart Bev is an all-inclusive process that includes deburring and inspection combined with super lattice, erosion-resistant, PVD products such as AlCrN-HC.

LET’S GET STARTED.

Ready to find the perfect tool, machining or PVD coating solution? Get started today.