QUICK TURNAROUND, PREMIUM PRODUCTS

We offer diverse services developed to support customers with quality job completion. Our team of specialists are in touch with you and provide a custom service tailored to your individual needs. From tool design and testing to surface preparation, PVD coating, and fast delivery, we have the expertise and ability to help you succeed at each step of your part process.

FAST DELIVERY

Your time is important. We proudly offer the fastest turnaround in our industry and provide flexible, free local pickup and delivery services. Contact us today to see when we will be in your area.

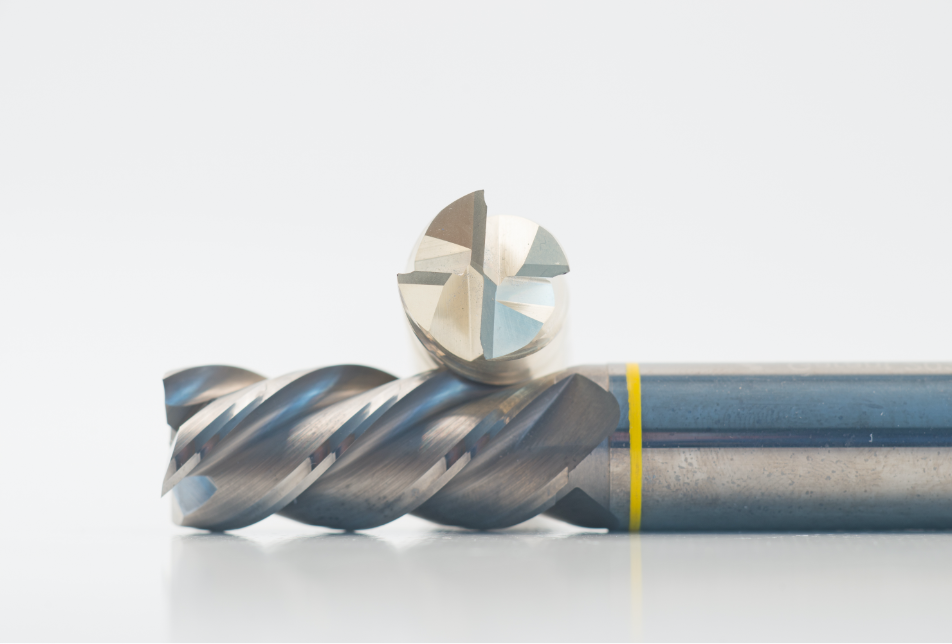

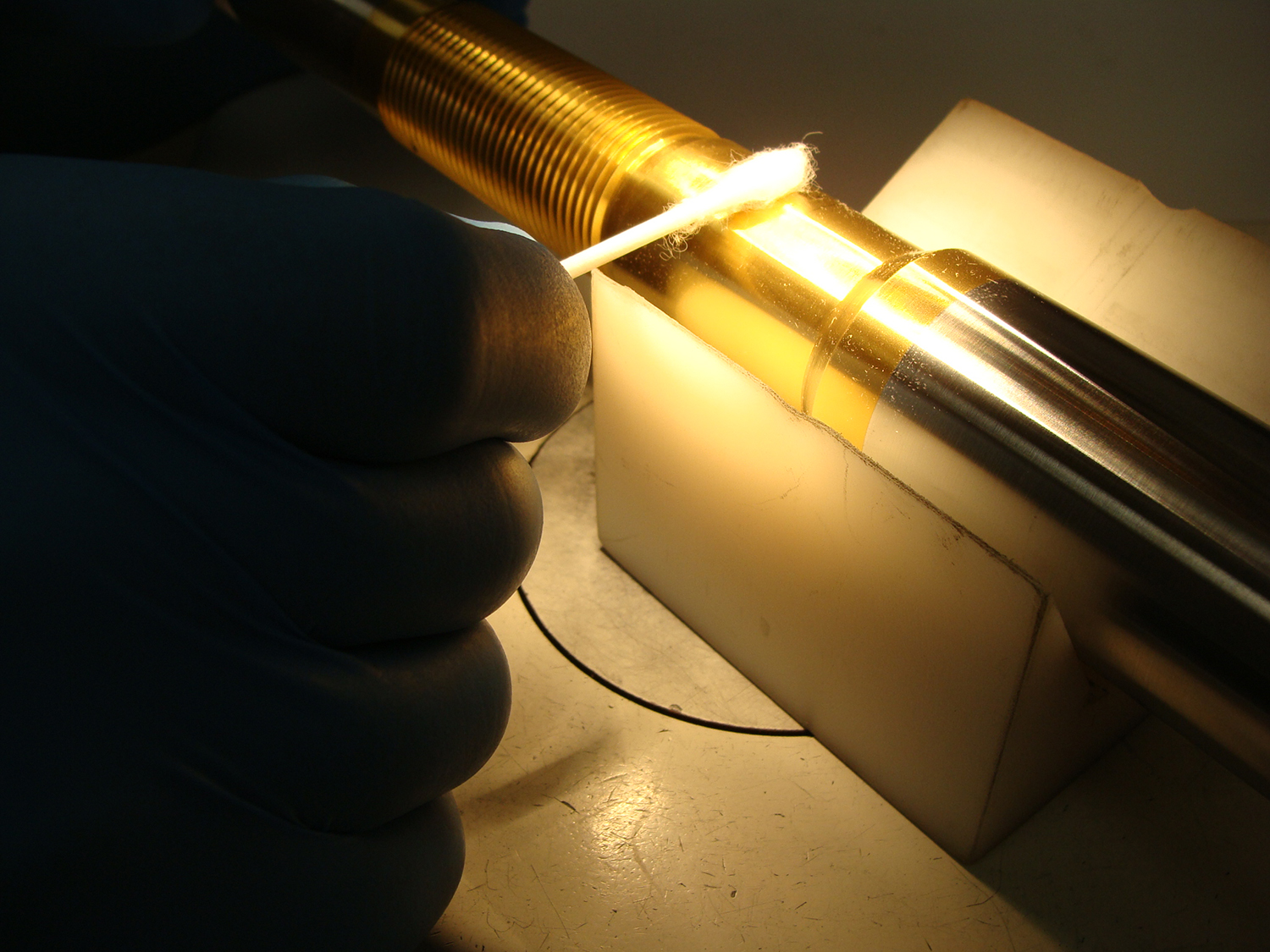

PVD COATING

We offer over 150 PVD coating formulations giving you a world of options to keep your precision parts performing at their peak.

A.T.M. (ADHESION, THICKNESS, MORPHOLOGY)

These are the things that matter. We pride ourselves in working with all of our customers to eliminate the techno double talk frequently seen in our industry. We want to understand your challenges, then provide real time solutions for you, without the smoke and mirrors. Let us help you better communicate your needs regarding Quality, Delivery, and Value with the respect your work deserves.

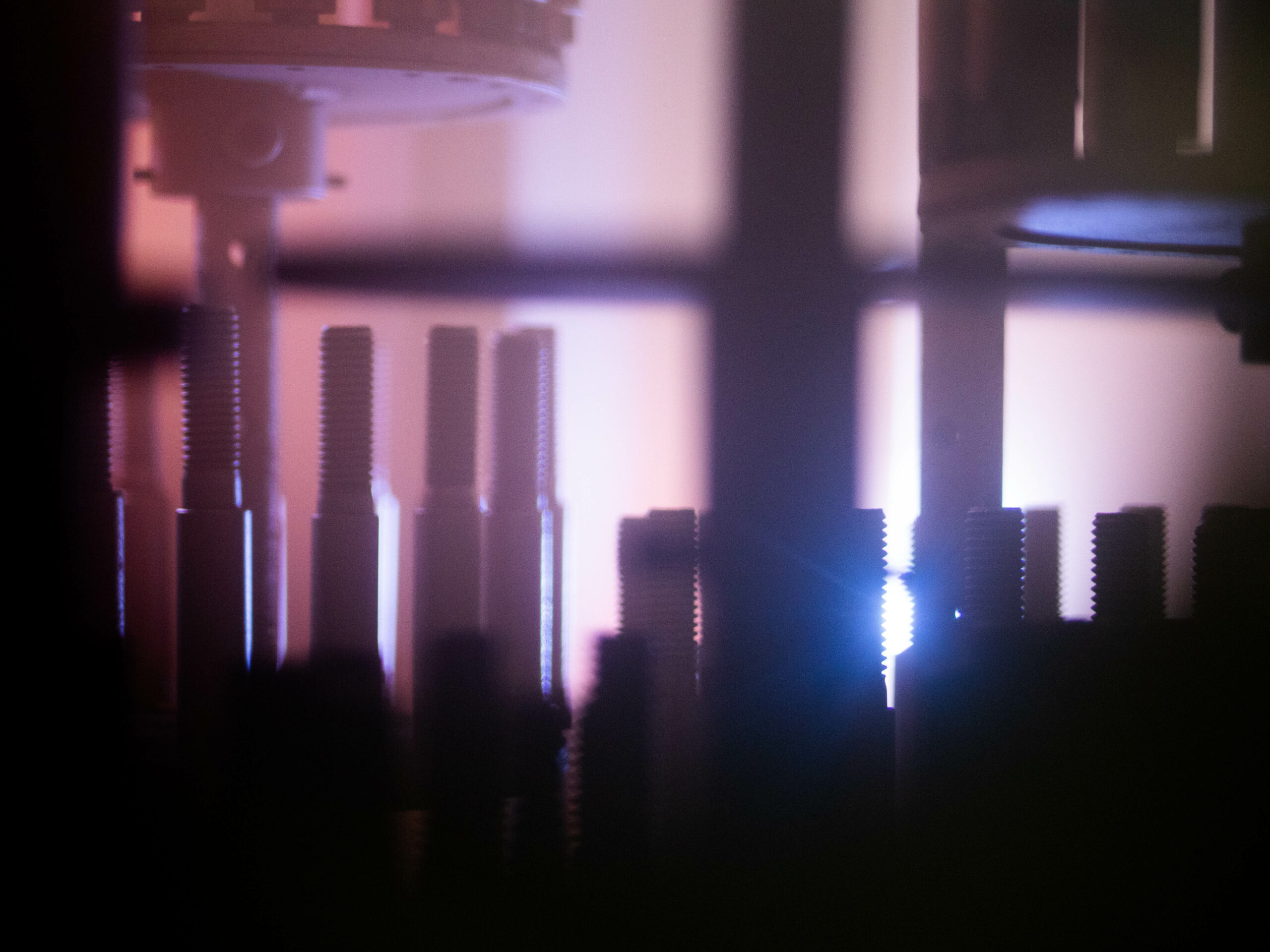

TIGHT TOLERANCE INSPECTION / PRECISION MASKING

All parts entering our facility are 100% inspected pre and post-production on state-of-the-art tribological quality equipment. We understand tight tolerance requirements and have a highly trained, dedicated staff of masking experts who guarantee crisp coating lines.

SURFACE PREPARATION

Our custom engineered surface preparations extend tool life and improve performance for all manufacturing processes. Surface preparation is key to adhesion and adhesion is the most important step of our PVD coating process. Thickness control is critical and we are the best at repeatable coatings with ±10% target thickness.

ADDITIONAL SERVICES

PVD Lube

Custom line of lube to enhance coated surface characteristics based on specific applications such as L36-MoS2, L35-Teflon, etc...

Edge Prep

Surface preparation from blasted to mirror finishes. A proprietary process of surface asperity reduction to enhance PVD coating performance.

Process Specifications

From basic time-consuming setups to the most advanced components, our engineers can design and deliver a complete finished progressive multifunction tool package

ATM

We want to understand your challenges, then provide real time solutions for you, without the smoke and mirrors. Let us help you better communicate your needs regarding Quality, Delivery, and Value with the respect your work deserves.

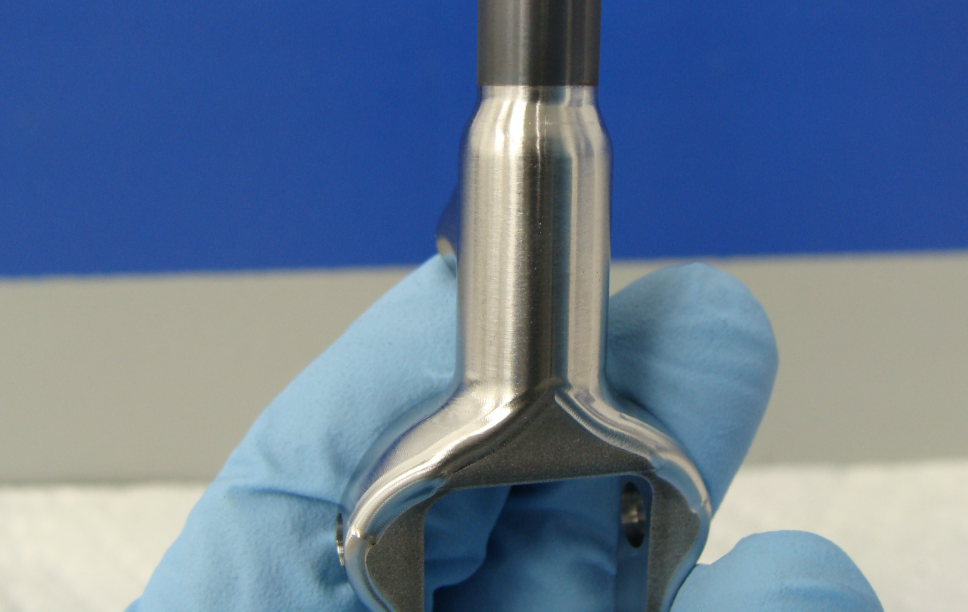

Vertical Integration

Machining, Grinding, Polishing, Heat Treating, and more to improve your finished product delivery.